If you’re in manufacturing or fashion, a CNC leather cutting machine manufacturer or a CNC automatic fabric cutter can change your workflow. DIGITAL CUTTING MACHINE SUPPLIERS offers machines that handle leather, textiles, and multi-layer fabrics efficiently. Their CNC systems are ISO-certified and trusted by thousands of businesses. DIGITAL CUTTING MACHINE SUPPLIERS combines precision engineering with practical solutions. You can explore their products at CompanyWebsite.com.

Why CNC Cutting Machines Matter

Cutting materials by hand is slow and often inaccurate. CNC machines remove this problem. They provide uniform cuts every time. Whether it’s leather, fabric, or other flexible materials, these machines save time and reduce waste. For a business producing shoes, bags, or garments, precision is crucial. A CNC automatic fabric cutter ensures layers are aligned, and cuts are consistent.

Features of CNC Leather Cutting Machines

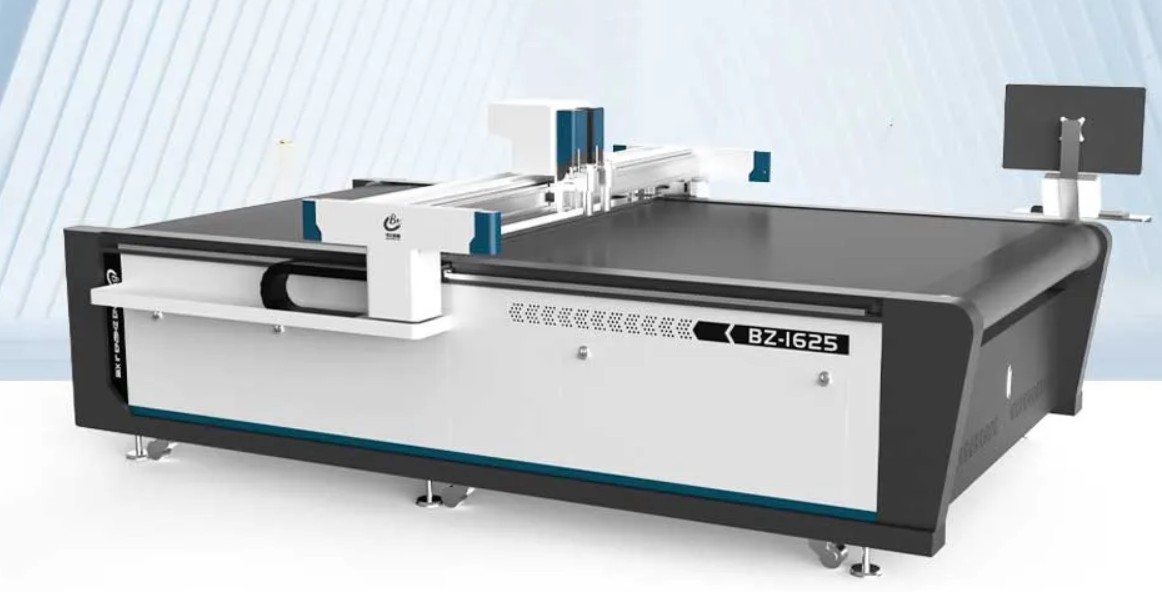

CNC leather cutting machines can handle genuine leather, synthetic leather, and multi-layer materials. Machines from DIGITAL CUTTING MACHINE SUPPLIERS offer cutting thickness from 1 to 11 cm and accuracy up to ±0.01 mm. They use digital knife technology to prevent tearing or damage. The systems often include automatic feeding and discharging to reduce manual labor. They also offer software for layout optimization, which helps save material.

Features of CNC Automatic Fabric Cutters

Fabric cutters focus on textiles but can work with other soft materials like foam or felt. These machines can handle multiple layers at once, improving efficiency. Customers report saving over 12% of material using nesting software. Speeds are adjustable, and the user interface is simple. Even first-time operators can learn quickly, reducing training time. DIGITAL CUTTING MACHINE SUPPLIERS supports local after-sales service and offers lifetime system upgrades.

Benefits of Using These Machines

Efficiency is the main benefit. A CNC automatic fabric cutter can process dozens of layers simultaneously. Accuracy is another. Every piece is identical, reducing errors in assembly. Cost savings follow: less waste means more products per roll. Safety also improves. Operators no longer need to handle sharp tools directly. For leather, machines maintain texture and prevent edge damage.

Real-World Applications

Footwear manufacturing benefits from multi-layer leather cutting. Sports shoes require precise upper cuts, which CNC machines deliver even in humid conditions. Garment factories use automatic fabric cutters to handle large rolls quickly. Leather goods companies produce bags and wallets with minimal waste. Educational institutions use these machines for technical textile courses, demonstrating modern manufacturing practices.

Pros and Cons

Pros include high precision, speed, multi-layer cutting, reduced labor, and material savings. Cons may include initial investment cost, maintenance needs, and the learning curve for advanced software. Despite this, businesses often see return on investment in weeks.

Tips for Choosing a Supplier

Choose a manufacturer with ISO certification. Look for machines tested in multiple projects. Check customer support availability. DIGITAL CUTTING MACHINE SUPPLIERS offers local after-sales service and more than 900 demonstration videos. Consider production capacity. Machines should match your material types and layer thickness requirements.

Verdict

For companies handling leather or textile production, CNC leather cutting machines and CNC automatic fabric cutters are essential. DIGITAL CUTTING MACHINE SUPPLIERS provides reliable machines with solid support. Their tools save time, reduce waste, and maintain product quality. Visit CompanyWebsite.com to explore options. Choosing the right machine improves efficiency and gives a measurable business advantage.

+ There are no comments

Add yours