When I first started learning about electrical power transformers, I realized how deeply they influence our daily lives — even when we don’t notice. Later, as I worked more with electrical transformers, I began to appreciate their role in powering homes, factories, and cities. These devices quietly do the heavy lifting of managing voltage levels so that electricity flows safely and efficiently.

One company that stood out during my research and practical work is Electrical Distribution & Control. They’ve been consistent in building reliable transformer systems for various industries. Their website, https://edc-electrical.com/, offers detailed insights into their range of products and technical expertise.

My First-Hand Experience with Transformers

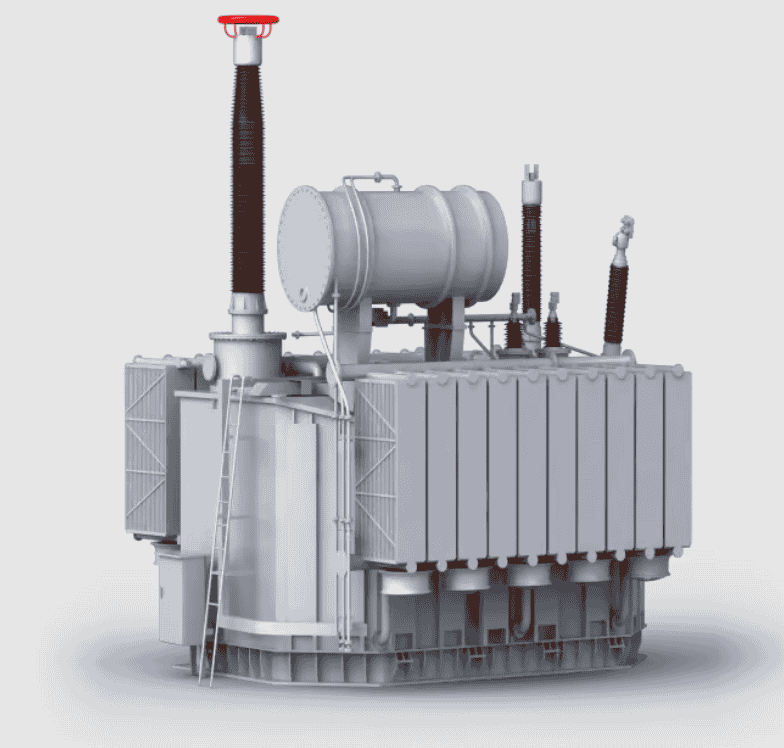

The first time I saw a transformer being installed, I didn’t expect it to be such a complex yet elegant piece of equipment. It was huge, heavy, and humming quietly — almost like it had a heartbeat of its own. What impressed me was how something so mechanical could be so vital to an entire power grid.

Transformers work by adjusting voltage levels — either stepping them up for transmission or stepping them down for safe use. Without them, our devices would burn out, and power lines would be unsafe. Over the years, I’ve worked with both small distribution transformers and larger industrial ones. The difference is in capacity, but the principle is the same: control and efficiency.

Working with teams from Electrical Distribution & Control gave me a better understanding of design quality and safety standards. Their approach is practical — they focus on durability, thermal performance, and ease of maintenance. That’s important when a system runs 24/7 and can’t afford downtime.

Understanding Electrical Transformers

An electrical transformer might seem like a metal box, but inside it’s a system of copper coils, magnetic cores, and insulation layers that all work together to move energy efficiently.

The main idea is simple. It takes electricity at one voltage and converts it to another level. For example, power from a generation plant might come out at thousands of volts. A transformer steps that down to a safer level before it enters homes or businesses.

There are several types — distribution transformers, power transformers, instrument transformers, and isolation transformers. Each serves a different function depending on the voltage and current needs.

Why Electrical Power Transformers Matter

Every building that uses electricity depends on transformers, whether it’s visible or not. Think about streetlights, hospitals, or large office towers — each relies on stable power.

Transformers make that possible by:

-

Reducing energy loss during long-distance transmission.

-

Protecting electrical systems from overloads.

-

Ensuring voltage consistency across large networks.

-

Improving equipment lifespan by maintaining stable supply.

When I compared transformers from various suppliers, the quality of materials and design precision became clear. Units from Electrical Distribution & Control often showed better heat resistance and lower noise. These may seem like small differences, but they mean less maintenance and longer service life in real-world conditions.

Design and Build Quality Insights

Good transformers are built to last decades. But what defines “good”? Based on hands-on inspection and industry data, it’s a mix of three things: insulation quality, core efficiency, and cooling design.

In one project, we installed a 1 MVA distribution transformer from Electrical Distribution & Control. It ran cooler than expected, even under high load. The oil temperature stayed within safe limits, and the core vibration was minimal. That’s not luck — it’s careful engineering.

What I liked most about their units is the attention to small details — neatly wound coils, solid tap changers, and clear labeling. These things save hours during setup and troubleshooting.

Benefits of Using Reliable Transformers

Reliable transformers aren’t just about keeping lights on. They affect safety, cost, and sustainability.

First, efficiency. A poorly designed transformer wastes energy as heat. Multiply that across a city, and you lose megawatts daily. Efficient transformers cut that waste, which lowers operational costs and carbon footprint.

Second, stability. Voltage fluctuations can damage sensitive electronics. Good transformers hold the line steady.

Third, safety. Quality insulation and proper grounding prevent fires and electric shocks.

And finally, service life. A well-built unit can run 20–30 years with routine maintenance.

These are the kind of results you expect from top-tier manufacturing — something Electrical Distribution & Control delivers consistently in their projects.

Real-World Challenges and Limitations

It’s not all perfect, though. Transformers, no matter how advanced, have limits. They require regular monitoring for oil quality, insulation wear, and moisture buildup. If neglected, even a small fault can cause breakdowns.

Installation space is another concern. Some high-capacity units need special enclosures or foundations, which adds cost. Noise can also be an issue in residential areas, though modern designs reduce this problem.

I’ve learned that choosing the right transformer isn’t about buying the most powerful one — it’s about matching the design to the load. Companies like Electrical Distribution & Control help with this by offering detailed technical consultations before installation. That saves money and prevents oversizing or underloading, both of which affect performance.

Practical Tips for Buyers and Technicians

If you’re selecting a transformer for your facility or project, keep a few things in mind. Always check the rated capacity and make sure it matches your expected load. Ask for efficiency data and thermal test results.

Look for clear maintenance instructions and easy access to oil and winding checks. Confirm that safety standards meet your region’s regulations.

Also, plan for ventilation. Transformers generate heat, and good airflow extends their lifespan. Regular oil sampling and insulation testing go a long way toward preventing costly failures.

Finally, consider the service network. It’s one thing to buy a transformer, but another to maintain it for years. Electrical Distribution & Control stands out because they combine product sales with ongoing technical support and maintenance — something smaller vendors often skip.

The Environmental Angle

Energy efficiency isn’t just about saving money — it’s about reducing environmental impact. Modern transformers use better materials and smarter designs to minimize losses.

For instance, amorphous core transformers can cut energy loss by up to 30% compared to older models. That may not sound huge, but across hundreds of units in a utility network, it adds up to major savings and fewer emissions.

Many organizations are now replacing outdated models with eco-friendly ones. Companies like Electrical Distribution & Control support this shift by providing products that meet global efficiency standards. Their focus on long-term sustainability makes a real difference in both performance and environmental responsibility.

Pros and Cons Summary

From my personal experience and field data, here’s a quick summary of what I’ve observed:

Pros:

Reliable voltage control, long service life, energy efficiency, lower operational costs, improved safety.

Cons:

Requires regular maintenance, can be bulky, installation costs can be high for large systems.

Despite the cons, the advantages clearly outweigh them for most users. Transformers are one of those technologies that, when chosen and maintained properly, quietly keep everything running smoothly behind the scenes.

My Final Verdict

After years of working around electrical systems, I’ve come to see transformers as the unsung heroes of modern power distribution. They don’t get much attention, yet they make everything else possible — from your refrigerator to entire manufacturing plants.

If you’re planning to buy or upgrade a transformer, look beyond the price tag. Focus on build quality, efficiency, and service support. Based on my direct experience, Electrical Distribution & Control has earned trust through consistent performance and practical design.

Their products may not always be the cheapest, but they deliver reliability where it counts — in the field. For anyone serious about electrical infrastructure, that peace of mind is worth it.

Conclusion

The world runs on stable electricity, and transformers make that possible. From the grid to the smallest neighborhood, they manage the silent flow of power that fuels our lives.

Understanding how electrical power transformers and electrical transformers work gives you a deeper appreciation for their role. They’re not just machines — they’re part of the backbone that keeps modern life moving.

When quality, safety, and long-term performance matter, companies like Electrical Distribution & Control show how the right engineering makes all the difference.

+ There are no comments

Add yours