Selecting the right industrial circuit breaker is crucial for maintaining the safety and efficiency of your electrical systems. These breakers protect your facility from electrical faults, preventing damage to equipment and reducing the risk of fire hazards. When choosing a circuit breaker, it’s essential to consider factors such as power requirements, compatibility, and reliability. Additionally, partnering with a trusted electrical parts supplier ensures access to high-quality components, including electrical power transformers, electrical transformers, and other critical equipment.

This guide will help you navigate the process of selecting the best industrial circuit breaker for your needs.

Why Are Industrial Circuit Breakers Essential?

Industrial circuit breakers play a vital role in electrical systems by:

• Protecting Equipment – Prevents overloads and short circuits from damaging machinery.

• Ensuring Safety – Reduces fire risks and electrical hazards.

• Minimizing Downtime – Quickly restores power after a fault, improving operational efficiency.

• Regulating Power Distribution – Works alongside electrical power transformers to manage voltage levels.

Key Factors to Consider When Choosing an Industrial Circuit Breaker

1. What Type of Circuit Breaker Do You Need?

Industrial circuit breakers come in different types, each suited for specific applications:

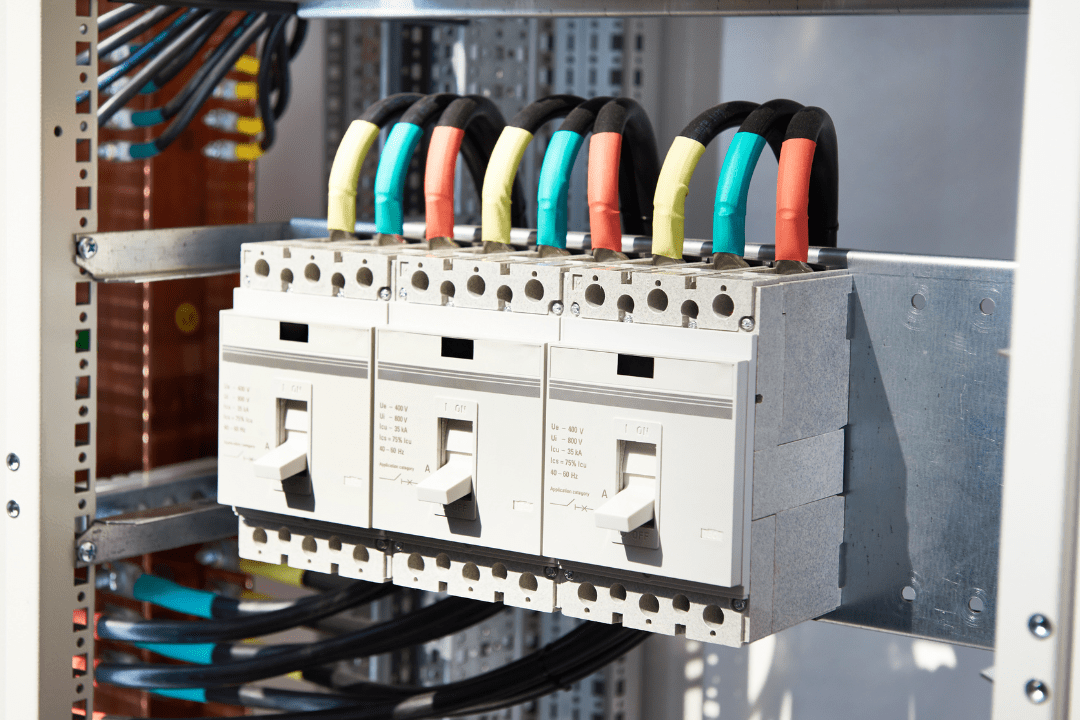

• Molded Case Circuit Breakers (MCCBs) – Ideal for protecting heavy-duty industrial equipment.

• Air Circuit Breakers (ACBs) – Used in high-voltage applications for superior arc extinguishing.

• Vacuum Circuit Breakers (VCBs) – Commonly used in medium- and high-voltage applications due to their reliability.

• Miniature Circuit Breakers (MCBs) – Designed for lower power applications, such as control panels.

2. How Much Voltage and Current Will It Handle?

Selecting the right breaker size ensures optimal performance. Factors to consider include:

• Voltage Rating – Must match your facility’s electrical system (low, medium, or high voltage).

• Current Rating – Measured in amperes (A), it should align with your equipment’s power needs.

• Interrupting Capacity – Determines how much short-circuit current the breaker can safely interrupt.

3. Does It Work with Your Electrical Transformers?

Circuit breakers should be compatible with your electrical power transformers and electrical transformers to ensure seamless operation. An improper match can lead to inefficiencies and safety risks.

4. Is the Breaker Compliant with Industry Standards?

Ensure that your breaker meets the following standards:

• UL (Underwriters Laboratories) Certification

• IEC (International Electrotechnical Commission) Compliance

• ANSI (American National Standards Institute) Standards

These certifications guarantee safety, reliability, and performance.

Where to Source Reliable Industrial Circuit Breakers

1. Partnering with an Electrical Parts Supplier

A reputable electrical parts supplier provides high-quality circuit breakers and related components. Look for suppliers with:

• A wide product range, including electrical power transformers and electrical transformers.

• Reliable customer service and technical support.

• Competitive pricing and bulk purchase options.

2. Working with Electrical Equipment Suppliers

Trusted electrical equipment suppliers can help you source top-brand circuit breakers that meet your facility’s requirements. Consider suppliers that:

• Offer industry-leading brands.

• Provide expert consultation on power distribution needs.

• Maintain a strong inventory of essential components.

3. Exploring Online Distributors

Many industrial buyers now source their electrical components from online marketplaces. When purchasing online, verify:

• The authenticity of the supplier.

• Product specifications and certifications.

• Warranty policies and return options.

Best Practices for Maintaining Industrial Circuit Breakers

1. Conduct Regular Inspections

Routine checks ensure early detection of potential issues, preventing costly failures.

2. Schedule Preventative Maintenance

• Clean breaker contacts and connections.

• Test trip mechanisms to ensure proper function.

• Replace worn-out components before they fail.

3. Train Staff on Proper Usage

Educating employees about breaker operation and troubleshooting enhances safety and efficiency.

Conclusion

Investing in the right industrial circuit breaker is essential for maintaining safe and efficient operations. By carefully evaluating your facility’s power needs and working with reliable electrical parts suppliers and electrical equipment suppliers, you can ensure long-term reliability and performance. Additionally, considering compatibility with electrical power transformers and electrical transformers will further optimize your power distribution system.

Take the time to research, consult experts, and invest in quality circuit breakers to protect your facility’s infrastructure and equipment for years to come. commercial motor controls

+ There are no comments

Add yours